PRODUCT SHOW

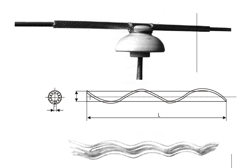

Heliformed armor rod

Armor Rods are intended to protect against bending,compression,abrasion, arc-over,and to provide repair.

Armor Rods are intended to protect against bending,compression,abrasion, arc-over,and to provide repair.The degree of protection needed on a specific line depends upon a number of factors such as line design,temperature,tension,exposure to wind flow, and vibration history on similar constrution in the same area.As a general guide,the following recommendations may be adopted to the specific conditions. Armor Rods are recommended as minimum protection for clamp-type supports or suspensions.

Line Guards are recommended as minmum protection for hand-tied spans.The use of supplementary damping devices,such as Spiral Vibration Dampers,should be considered whenconductor vibration is present or expected.

Safety considerations

1.This product is intended for a single(one-time) use and for the specified application.

2.This product is intended or use by trained craftspeople only.This product should not be used by anyone who is not farmiliar with and tranined in the use of if .

3.Whe working in the area of energized lines with this Product,extra care should be taken to prevent Accidental electrical contact.

4.For proper performance and personal Safety be sure to selectthe proper size Performed armor rods before application.

5.Preformed armor rods are precision devices.To insure proper performance,they should be stored in Cartons under cover and handled carefully.

6.The armor rod can use with much fitting.

7.If you have any question please contact with Laurence Electric Power Equipment Co.,Ltd.

Double suspension clamp for ASCR AAC

| catalogue number | Suitable conductor GB1179-83 | Dimensions(mm) | Weight (kg) |

||||

| ACSR LGJ/LGJF | LGJJ | AAC/LJ | D | d | L | ||

| FYH-95/15 | LGJ-95/15 | 3.6 | 11.4 | 1400 | 0.5 | ||

| FYH-95/20 | LGJ-95/20 | 3.6 | 11.4 | 1400 | 0.5 | ||

| FYH-95/55 | LGJ-95/55 | 3.6 | 13.3 | 1500 | 0.6 | ||

| FYH-120/7 | LGJ-120/7 | 120 | 3.6 | 12.0 | 1400 | 0.6 | |

| FYH-120/20 | LGJ-120/20 | 3.6 | 12.5 | 1400 | 0.6 | ||

| FYH-120/25 | LGJ-120/25 | 3.6 | 13.0 | 1400 | 0.6 | ||

| FYH-120/70 | LGJ-120/70 | 4.6 | 14.9 | 1800 | 0.8 | ||

| FYH-150/8 | LGJ-150/8 | 150 | 150 | 3.6 | 13.3 | 1500 | 0.6 |

| FYH-150/20 | LGJ-150/20 | 3.6 | 14.7 | 1500 | 0.7 | ||

| FYH-150/25 | LGJ-150/25 | 3.6 | 14.2 | 1500 | 0.7 | ||

| FYH-150/35 | LGJ-150/35 | 4.6 | 14.5 | 1500 | 0.7 | ||

| FYH-185/10 | LGJ-185/10 | 185 | 185 | 4.6 | 14.9 | 1800 | 1.2 |

| FYH-185/25 | LGJ-185/25 | 4.6 | 15.7 | 1800 | 1.3 | ||

| FYH-185/30 | LGJ-185/30 | 4.6 | 15.7 | 1800 | 1.3 | ||

| FYH-185/45 | LGJ-185/45 | 4.6 | 16.3 | 1800 | 1.3 | ||

| FYH-210/10 | LGJ-210/10 | 210 | 4.6 | 15.9 | 1800 | 1.3 | |

| FYH-210/25 | LGJ-210/25 | 4.6 | 16.6 | 1800 | 1.3 | ||

| FYH-210/35 | LGJ-210/35 | 4.6 | 16.9 | 1800 | 1.3 | ||

| FYH-210/50 | LGJ-210/50 | 4.6 | 17.3 | 1800 | 1.3 | ||

| FYH-240/30 | LGJ-240/30 | 240 | 240 | 4.6 | 17.9 | 1900 | 1.4 |

| FYH-240/40 | LGJ-240/40 | 4.6 | 17.9 | 1900 | 1.4 | ||

| FYH-240/55 | LGJ-240/55 | 4.6 | 18.6 | 1900 | 2.3 | ||

| FYH-300/15 | LGJ-300/15 | 300 | 300 | 6.3 | 19.1 | 2000 | 2.3 |

| FYH-300/20 | LGJ-300/20 | 6.3 | 19.4 | 2000 | 2.3 | ||

| FYH-300/25 | LGJ-300/25 | 6.3 | 19.8 | 2000 | 2.3 | ||

| FYH-300/40 | LGJ-300/40 | 6.3 | 19.9 | 2000 | 2.3 | ||

| FYH-300/50 | LGJ-300/50 | 6.3 | 20.1 | 2000 | 2.3 | ||

| FYH-300/70 | LGJ-300/70 | 6.3 | 20.9 | 2000 | 2.3 | ||

| FYH-400/20 | LGJ-400/20 | 400 | 400 | 6.3 | 22.3 | 2200 | 2.8 |

| FYH-400/25 | LGJ-400/25 | 6.3 | 22.1 | 2200 | 2.8 | ||

| FYH-400/35 | LGJ-400/35 | 6.3 | 22.3 | 2200 | 2.8 | ||

| FYH-400/50 | LGJ-400/50 | 6.3 | 23.0 | 2200 | 2.8 | ||

| FYH-400/65 | LGJ-400/65 | 6.3 | 23.2 | 2200 | 2.8 | ||

| FYH-400/95 | LGJ-400/95 | 6.3 | 24.8 | 2500 | 2.8 | ||

| FYH-500/35 | LGJ-500/35 | 500 | 7.8 | 24.9 | 2500 | 3.5 | |

| FYH-500/45 | LGJ-500/45 | 7.8 | 24.9 | 2500 | 3.5 | ||

| FYH-500/65 | LGJ-500/65 | 7.8 | 25.7 | 2500 | 3.5 | ||

| FYH-630/45 | LGJ-630/45 | 7.8 | 27.9 | 2500 | 5.3 | ||

| FYH-630/55 | LGJ-630/55 | 7.8 | 28.5 | 2500 | 5.3 | ||

| FYH-630/80 | LGJ-630/80 | 7.8 | 28.9 | 2500 | 5.3 | ||

| FYH-800/55 | LGJ-800/55 | 7.8 | 31.8 | 2500 | 6.0 | ||

| FYH-800/70 | LGJ-800/70 | 7.8 | 32.1 | 2500 | 6.0 | ||

| FYH-800/100 | LGJ-800/100 | 7.8 | 32.3 | 2500 | 6.0 | ||

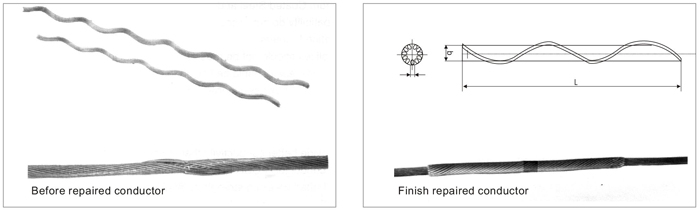

The repaired armor rod was use for Repair of damaged distribution line phase and neutral conductors

Damage to distribution line phase and neutral conductor can occur in service for a number of reasons,including:

Aeolian vibration and galloping

Loose hand ties

Lightning strikes

Contact from trees or other objects

Firearms

The re-conductoring is not required.In most cases the repair solution will depend on the extent of the damage. Therefore,the first step in any repair is an accurate assessment of the level of damage.Gener ally an ac curate ass essment of the number of damaged or broken strands can be made by a close visual inspection,with the tension relieved in the damaged area.Since damage can be hidden under ties or support hardware it is usually necessary to carefully remove this hardware to completely assess the amount of damage.

The application steps for eletrical repair:

Step 1:Thoroughly wire-brush damaged conductor for the full length of the Aromor Rods to be applied.

Step 2:Apply a gritted inhibitor to the full length of this area before applying the repaired Armor Rods.

| catalogue number | Dimensions(mm) | Groups for each | Weight (kg) |

|||

| D | d | L | ||||

| FYH-95/15 | LGJ-95/15 | 3.6 | 11.4 | 420 | 13 | 0.14 |

| FYH-95/20 | LGJ-95/20 | 3.6 | 11.4 | 420 | 13 | 0.16 |

| FYH-95/55 | LGJ-95/55 | 3.6 | 13.3 | 420 | 16 | 0.17 |

| FYH-120/7 | LGJ-120/7 | 3.6 | 12.0 | 450 | 14 | 1.18 |

| FYH-120/20 | LGJ-120/20 | 3.6 | 12.5 | 450 | 14 | 0.18 |

| FYH-120/25 | LGJ-120/25 | 3.6 | 13.0 | 450 | 14 | 0.18 |

| FYH-150/8 | LGJ-150/8 | 3.6 | 13.3 | 480 | 16 | 0.20 |

| FYH-150/20 | LGJ-150/20 | 3.6 | 14.8 | 480 | 16 | 0.21 |

| FYH-150/25 | LGJ-150/25 | 3.6 | 14.2 | 480 | 16 | 0.21 |

| FYH-150/35 | LGJ-150/35 | 3.6 | 14.5 | 480 | 16 | 0.21 |

| FYH-35 | LGJ-35 | 3.6 | 7.1 | 270 | 9 | 0.08 |

| FYH-50 | LGJ-50 | 3.6 | 8.2 | 300 | 10 | 0.09 |

| FYH-70 | LGJ-70 | 3.6 | 9.7 | 340 | 11 | 0.12 |

| FYH-95 | LGJ-95 | 4.6 | 11.6 | 420 | 11 | 0.23 |

| FYH-120 | LGJ-120 | 4.6 | 12.9 | 450 | 12 | 0.27 |

| FYH-150 | LGJ-150 | 4.6 | 14.4 | 480 | 13 | 0.30 |

| FYH-185 | LGJ-185 | 4.6 | 16.2 | 580 | 14 | 0.39 |

| FYH-240 | LGJ-240 | 6.3 | 18.4 | 640 | 12 | 0.66 |

| FYH-300 | LGJ-300 | 6.3 | 20.5 | 700 | 13 | 0.80 |

| FYH-400 | LGJ-400 | 6.3 | 23.8 | 820 | 14 | 1.05 |