|

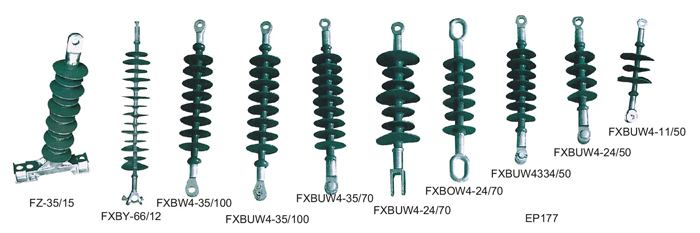

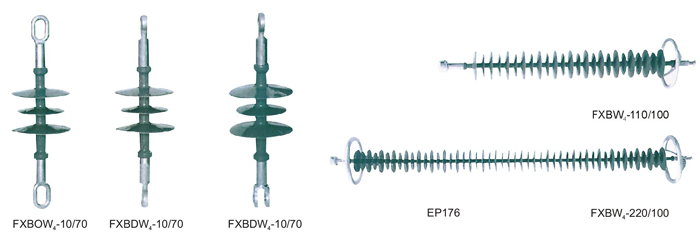

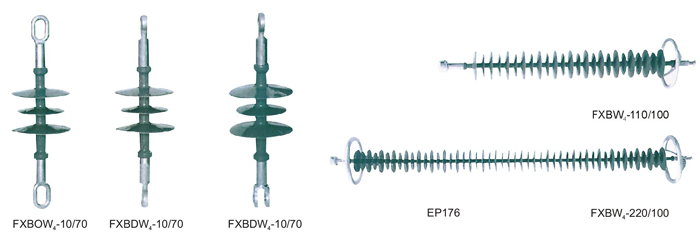

1.End Fitting:The fitting connection adopts the zinc cover protection,supersonic monitor and coaxial constant compression controlled by computer,finished with good appearance and high quality.

2.The silicon rubber rain shed,designed according to the aerodynamics principle,use the whole-molding method,to make sure the validity of total creepage distance every climate and nasty conditions,as well as improve the pollution discharge of the insulators .

3.The average thickness of protective cover¡Ý5mm£¬comply with IEC standard.

4.Fiber rod:uses the ECR high-temperature and acid-proof fiber fod.

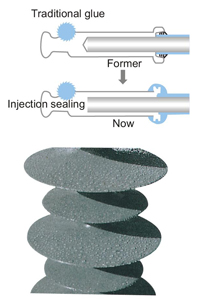

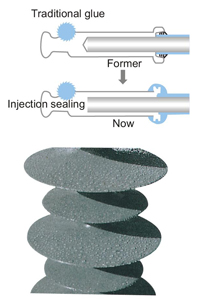

5.The end fitting uses maze type waterproof design,and out-cover rubber process,which enhanced the product waterproof greatly.

|

|

|

The fittings made by special steel,together with advanced compression technique,ensuring the stability and accurate of insulators. |

|

|